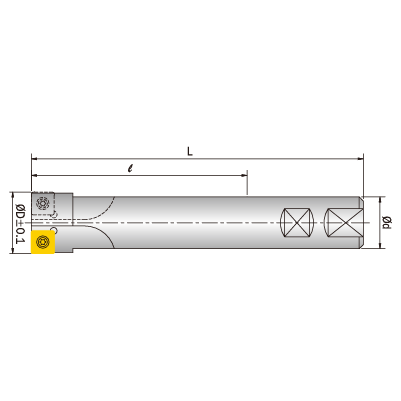

刀桿

| Order No. | Part No. | ?D | ?d | ? | L | 刀片 | 螺絲 / 板手 |

|---|---|---|---|---|---|---|---|

| 99002-015 | SB16 - TB15-N9 | 14.7 | 16 | 50 | 98 | N9MT06T203 |

NS-25045 0.9Nm / NK-T7 |

| 99002-016 | SB16 - TB16-N9 | 15.7 | |||||

| 99002-017 | SB16 - TB17-N9 | 16.7 | |||||

| 99002-018 | SB16 - TB18-N9 | 17.7 | |||||

| 99002-019 | SB16 - TB19-N9 | 18.7 | 16 | 62 | 110 | ||

| 99002-020 | SB16 - TB20-N9 | 19.7 | |||||

| 99002-021 | SB16 - TB21-N9 | 20.7 | 16 | 62 | 110 |

NS-25060 0.9Nm / NK-T7 |

|

| 99002-022 | SB16 - TB22-N9 | 21.7 | |||||

| 99002-023 | SB20 - TB23-N9 | 22.7 | 20 | 70 | 120 | ||

| 99002-024 | SB20 - TB24-N9 | 23.7 |

| Order No. | Part No. | ?D | ?d | ? | L | 刀片 | 螺絲 / 板手 |

|---|---|---|---|---|---|---|---|

| 99002-025 | SB20 - TB25-N9 | 24.7 | 20 | 70 | 120 | N9MT11T308 |

NS-35080 2.5Nm / NK-T15 |

| 99002-026 | SB20 - TB26-N9 | 25.7 | |||||

| 99002-028 | SB20 - TB28-N9 | 27.7 | |||||

| 99002-030 | SB25 - TB30-N9 | 29.7 | 25 | 104 | 160 | ||

| 99002-032 | SB25 - TB32-N9 | 31.7 | |||||

| 99002-035 | SB25 - TB35-N9 | 34.7 | |||||

| 99002-037 | SB25 - TB37-N9 | 36.7 | |||||

| 99002-040 | SB25 - TB40-N9 | 39.7 | |||||

| 99002-042 | SB32 - TB42-N9 | 41.7 | 32 | 140 | 200 | ||

| 99002-045 | SB32 - TB45-N9 | 44.7 | |||||

| 99002-047 | SB32 - TB47-N9 | 46.7 | |||||

| 99002-050 | SB32 - TB50-N9 | 49.7 | |||||

| 99002-052 | SB42 - TB52-N9 | 51.7 | 42 | 150 | 220 | ||

| 99002-055 | SB42 - TB55-N9 | 54.7 | |||||

| 99002-058 | SB42 - TB58-N9 | 57.7 | |||||

| 99002-060 | SB42 - TB60-N9 | 59.7 | |||||

| 99002-062 | MC25 - 62-N9 | 61.7 | 25.4 | - | 50 | ||

| 99002-065 | MC25 - 65-N9 | 64.7 | |||||

| 99002-070 | MC25 - 70-N9 | 69.7 | |||||

| 99002-080 | MC25 - 80-N9 | 79.7 | |||||

| 99002-090 | MC25 - 90-N9 | 89.7 | |||||

| 99002-100 | MC25 - 100-N9 | 99.7 |

切削資料

| 工件材質(zhì) | 加工狀況 | 刀片材種 | 線速 Vc (m/min) | 二刃進(jìn)給 (每轉(zhuǎn)) | |

|---|---|---|---|---|---|

| 碳鋼 | 一般切削 | NC40 | 100 (80~120) | 0.20 (0.20~0.40) | |

| 合金鋼 | 一般切削 | NC2033 | 100 (80~100) | 0.20 (0.20~0.30) | |

| 不鏽鋼 | 一般切削 | NC2033 | 80 (70~100) | 0.20 (0.20~0.30) | |

| 鑄鐵 | 一般切削 | NC2033 | 100 (80~120) | 0.20 (0.20~0.30) | |

| 鋁合金 | 一般切削 | NC9031 | 150 (130~200) | 0.20 (0.20~0.40) | |

| 工件材質(zhì) | 加工狀況 | 刀片材種 | 線速 Vc (m/min) | 二刃進(jìn)給 (每轉(zhuǎn)) | |

|---|---|---|---|---|---|

| 碳鋼 | 一般切削 | NC40 | 100 (80~120) | 0.25 (0.20~0.40) | |

| 耐磨鍍層 | NC35 | 120 (100~140) | 0.25 (0.20~0.40) | ||

| 合金鋼 | 耐磨(瓷金) | NC60 | 150 (120~180) | 0.20 (0.15~0.25) | |

| 一般切削 | NC40 | 100 (80~100) | 0.25 (0.20~0.30) | ||

| 耐磨鍍層 | NC35 | 120 (100~140) | 0.25 (0.20~0.30) | ||

| 不鏽鋼 | 一般切削 | NC40 | 80 (70~100) | 0.25 (0.20~0.30) | |

| 鑄鐵 | 一般切削 | NC10 | 100 (80~120) | 0.30 (0.25~0.50) | |

| 鋁合金 | 一般切削 | NC10 | 150 (130~200) | 0.25 (0.20~0.40) | |

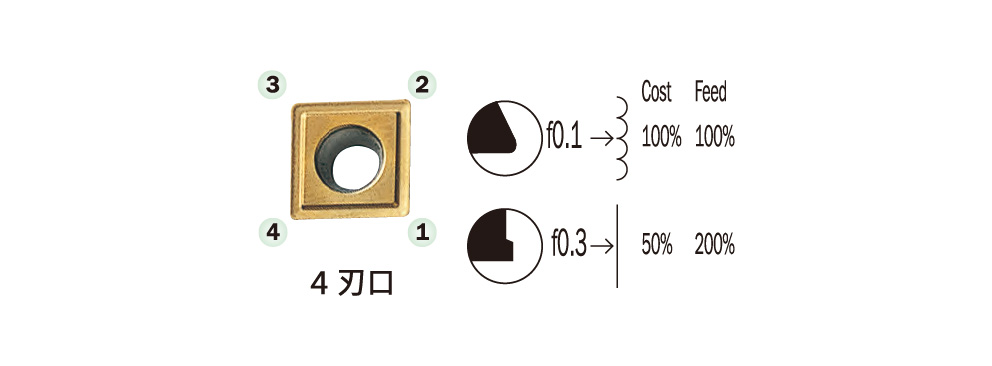

N9MT...

刀片

| Order No. | 尺寸 | ||||

|---|---|---|---|---|---|

| L | S | Re | |||

|

N9MT06T203 鋼材單邊預(yù)留小於1mm |

NC40 |

|

6.35 | 2.78 | 0.3 |

| N9MT06T203 | NC2033 | ||||

| NC9031 | |||||

| Order No. | 尺寸 | ||||

|---|---|---|---|---|---|

| L | S | Re | |||

|

N9MT11T308 斷屑型(一般) |

NC60 |

|

11.11 | 3.97 | 0.8 |

| NC40 | |||||

| NC10 | |||||

|

N9MT11T308LA 低阻抗型 |

NC60 | 11.11 | 3.97 | 0.8 | |

| NC40 | |||||

| NC35 | |||||

|

NC10 |

|||||

N9MT...

N9MT...